Failure analysis

Maiwald Engineering helps you to analyse the causes of damage to components (component failure). In addition, we develop safe and viable remedies for you!

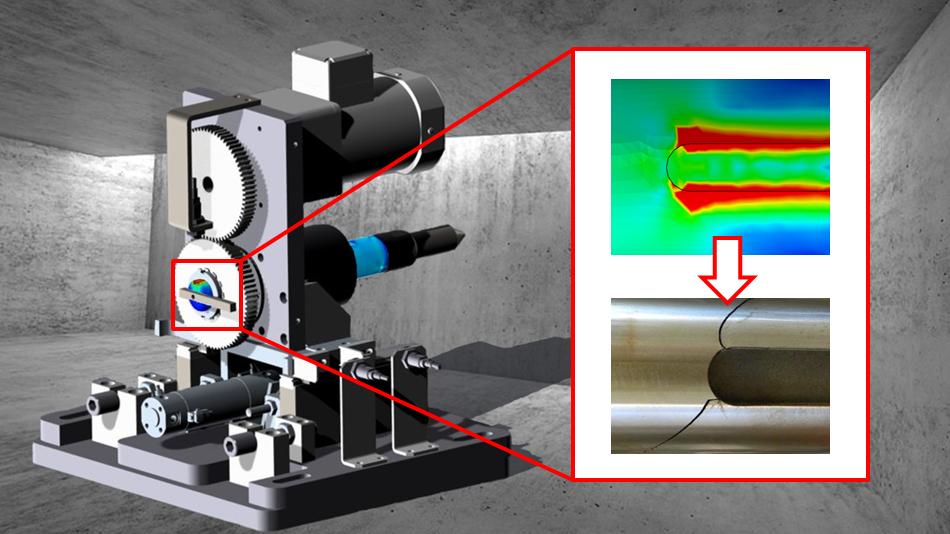

While purely static overloads are relatively easy to identify or exclude, dynamic overloads provide a quite complex topic. Particularly challenging

in this case is consideration of the surfaces in contact.

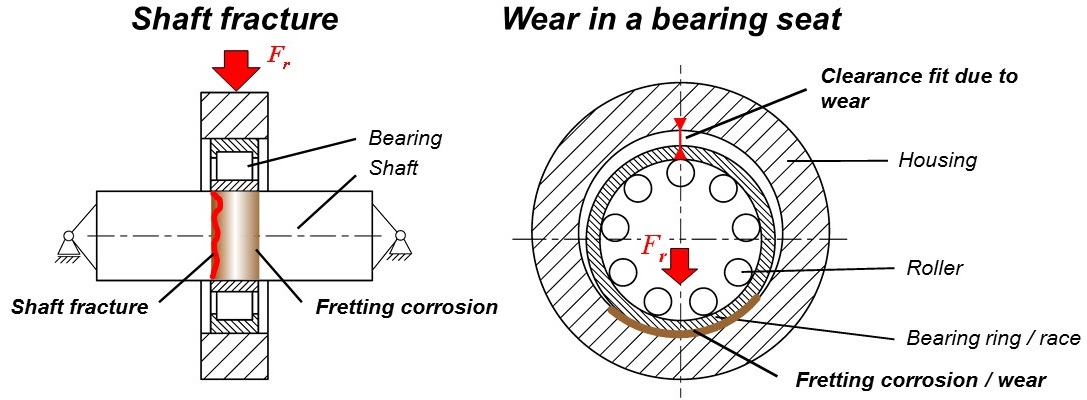

On dynamically loaded metallic contact surfaces fretting corrosion can occur due to slippage. Therefore, partial shifts between the contact surfaces

can lead to abrasion, which is oxidised to fretting corrosion by atmospheric oxygen. Subsequently, cracks may appear on the surface or near the surface,

which can ultimately lead to a fretting fatigue fracture. Likewise, fretting wear can generate a clearance fit in contact, which can lead to a failure of

components. Maiwald Engineering analyses such damages and develops feasible remedies. If necessary, experimental investigations are carried out in cooperation

with the Technical University of Chemnitz to determine required input parameters for the simulation or material-dependent strength parameters.

Examples of tribological initiated damages