Slippage simulation

Slippage usually cannot be eliminated in the contact area of dynamically loaded assemblies. However, the uncertainties about possible consequences by now!

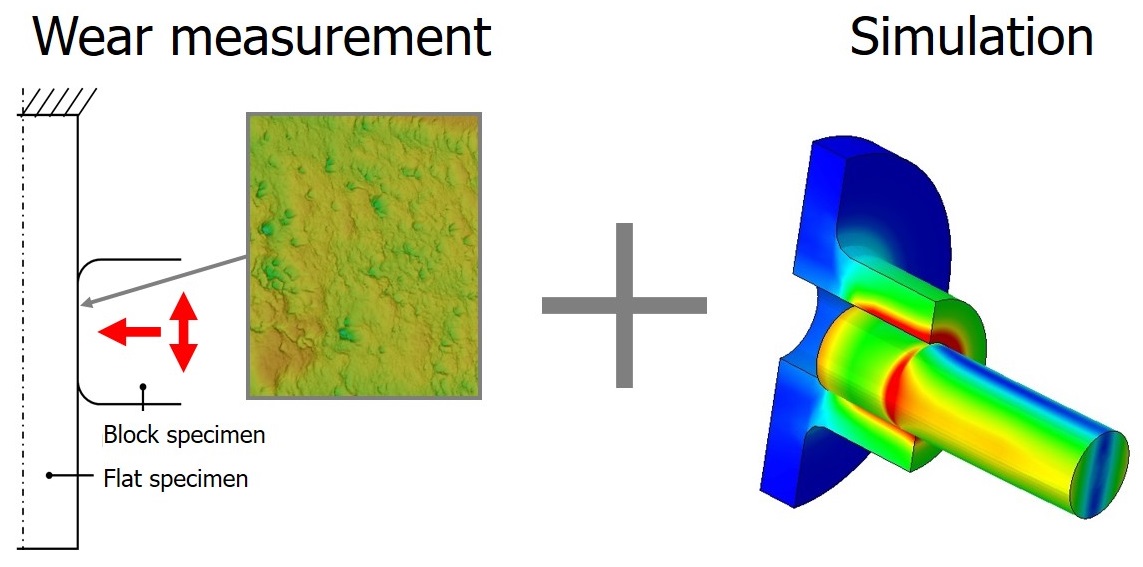

For two components in contact, reversible or irreversible slip movements can occur. For reversible (i.e. returning to their point of origin) micro movements (slippage) usually the surface wear is in the foreground. If the wear becomes too large, a loss of contact pressure and thus a failure of the connection can occur. With the unique combination of standardized wear measurements and realistic contact simulations, Maiwald Engineering offers the possibility to detect wear-critical contacts and to determine appropriate remedial measures. Due to the chosen approach, we do not need any tests on the real component for the determination of the operating life wear. Thus, the appraisal of the contact behaviour is already possible in the design phase of your application!

Determination of critical contacts by combination of experiment and simulation

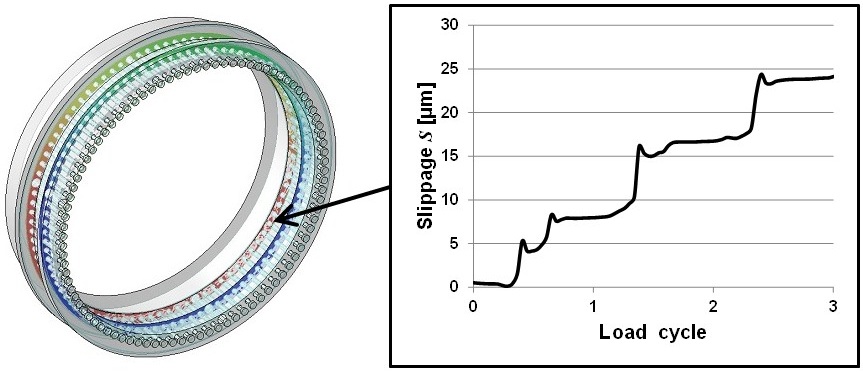

Irreversible (i.e. accumulative) micro movements lead in most applications to serious problems or even to failure of the machine. In the image, a corresponding critical application is shown, which is loaded dynamically. Due to the irreversible slippage between the components shown in the diagram, the bolts are subjected to shear. This leads to failure of the bolts and therefore the entire machine.

Exemplary slippage curve of a multi bolt connection under dynamic loading

The realistic simulation of slippage resp. relative movements between contacting components requires extensive simulative as well as tribological know-how. Maiwald Engineering offers you the expertise of various tribological coefficient of friction and wear tests together with an experimentally confirmed simulation methodology. Whether a bolted connection, shaft-hub press fit or form closure element, Maiwald Engineering is your competent partner!